Revolutionizing the Printing Industry: The Significance of Grooving Machines

The printing industry, characterized by its demand for precision and speed, is an ever-evolving field that constantly seeks innovation and improvement. In this context, grooving machines play a critical role in the processing of paper and cardboard, essential for the folding, joining, and finishing of printed products. This article will delve into the importance, functionality, and benefits of grooving machines within the printing sector.

The Fundamental Function of Grooving Machines

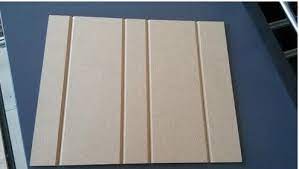

Grooving machines are designed to create precise and uniform grooves on materials such as paper or cardboard. These grooves facilitate the folding or joining of printed products. They are indispensable in the production of hardcover books, boxes, envelopes, and various packaging materials.

Their Place in the Printing Industry

The printing industry is defined by rapidly changing consumer demands and high-quality standards. Grooving machines hold a significant place in meeting these demands, marrying aesthetics with functionality in product output. By offering high precision and speed, they optimize the production processes of printed materials.

Technological Advances and Adaptation

With technological advancements, grooving machines have been equipped with more sophisticated features. The integration of CNC (Computer Numerical Control) technology allows for operations with higher precision and fewer errors. Furthermore, the inclusion of automation and smart sensors enhances the efficiency and reliability of production processes.

Advantages

The advantages provided by grooving machines to the printing industry are multifaceted:

- Precision: The high precision of grooves ensures perfect folding and joining processes.

- Efficiency: Their rapid processing capacity accelerates production processes and reduces costs.

- Flexibility: The ability to work on materials of different thicknesses and types increases product diversity.

- Quality: Elevates the aesthetic and functional quality of the final products, enhancing consumer satisfaction.

Conclusion

The printing industry is undergoing a revolution with the technological capabilities provided by grooving machines. These devices are indispensable for printing operations that aim to meet high-quality standards, optimize production costs, and strengthen their competitive position in the market. The use of grooving machines promises continuous improvement in the quality and processing speed of printed products, marking a significant step forward in the advancement of printing technologies and the production of superior-quality printed materials.