Unveiling Grooving Machinery: Key to Precision and Efficiency in Modern Manufacturing

Grooving machinery, a pivotal tool in modern manufacturing, enhances precision and efficiency in fabricating various materials. This specialized equipment plays a crucial role in industries ranging from metalworking to woodworking, offering unparalleled accuracy and speed. This article explores the innovative features, operational benefits, and diverse applications of grooving machinery in today’s industrial landscape.

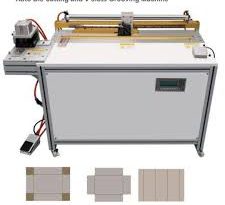

Technological Advancements in Grooving Machinery

Recent advancements in grooving machinery have focused on enhancing accuracy, speed, and versatility. Modern machines now incorporate CNC (Computer Numerical Control) technology, which allows for precise control over the grooving process, ensuring uniformity and quality across large production volumes. Additionally, the integration of laser-guided systems and robotic arms has improved the precision of cuts while reducing human error and increasing safety.

Operational Benefits of Advanced Grooving Machinery

The introduction of advanced grooving machinery in manufacturing processes has led to significant improvements in production efficiency. These machines reduce the time required for grooving operations, enabling faster turnaround times for large-scale projects. Furthermore, their ability to handle multiple functions, such as cutting, milling, and grooving in a single setup, minimizes equipment changeover, thus optimizing workflow and reducing operational costs.

Applications Across Industries

Grooving machinery is versatile, finding utility in numerous sectors. In the metalworking industry, it is essential for creating precise grooves in components for automotive and aerospace applications, where exact tolerances are critical. In the woodworking sector, grooving machines are used to fabricate cabinetry and furniture with intricate designs and durable joints. Additionally, these machines are increasingly used in the production of high-grade polymer and composite materials, which are common in modern construction and product design.

Future Trends: Automation and Material Innovation

The future of grooving machinery is closely tied to trends in automation and material innovations. As industries push for higher productivity and reduced labor costs, fully automated grooving machines equipped with AI are expected to become more prevalent. These machines will likely be designed to adapt to new and advanced materials, including lightweight composites and environmentally friendly alternatives, further broadening their application scope.

Conclusion

Grooving machinery is indispensable in modern manufacturing, driving innovation and efficiency across various industries. With ongoing advancements in technology and material sciences, these machines are set to become even more critical in the production landscape, offering faster, safer, and more cost-effective solutions. As we move forward, the evolution of grooving machinery will continue to influence the standards and capabilities of industrial manufacturing.