Grooving Machines: The Key to Industrial Transformation

- Introduction: The Role of Grooving Machines in Industrial Design

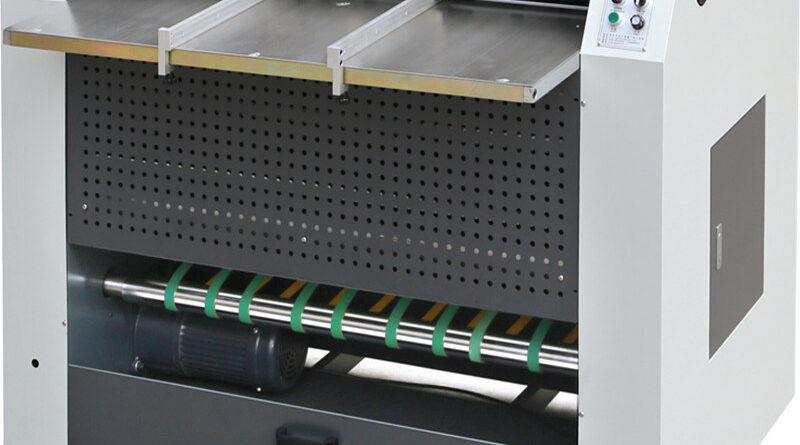

Grooving machines play a pivotal role in facilitating folding and assembly processes by creating precise grooves on materials such as paper, cardboard, and corrugated board. This article delves into how these machines have revolutionized industrial design and manufacturing. - Evolution of Technology: Advances in Grooving Machines

The evolution of technology has made grooving machines more efficient and user-friendly. Enhanced control systems and automation features have made them indispensable in modern production lines. - Diversity and Adaptation: Machines for Different Sectors

Grooving machines offer adaptable features for various sectors, from packaging to construction, automotive to furniture production. This versatility ensures a wide range of applications. - Operational Efficiency: Impact on Production Processes

In terms of operational efficiency, grooving machines accelerate production processes and enable higher output with less labor, leading to cost savings, especially in large-scale productions. - Precision and Quality: Effects on Product Quality

The grooving process ensures materials are folded more accurately and neatly, directly affecting the quality of the final product and customer satisfaction. - Innovation and Design: Creative Solutions

Grooving machines provide designers and manufacturers the opportunity to use materials in new and creative ways, paving the way for innovative solutions in customized packaging and product design. - Sustainable Production: Environmental Impacts

As demand for sustainable production practices grows, grooving machines offer significant advantages in reducing energy consumption and material waste, helping to minimize environmental footprint. - Education and Skill Development: Contributions to the Workforce

The use of grooving machines requires technical knowledge and skills, creating opportunities for education and skill development and contributing to the cultivation of specialized professionals in industrial design. - Future Outlook: Technological Developments and Trends

Future advancements in grooving technology will enable even higher efficiency, automation, and adaptability, shaping critical trends in industrial production and design. - Conclusion: The Impact of Grooving Machines on Industry

Grooving machines are set to continue leading the charge in industrial transformation. With ongoing technological advancements and an increasing demand for innovative and sustainable production methods, these machines are crucial for shaping the future of industrial design and manufacturing.

Grooving machine