Precision and Efficiency: The Role of Grooving Machines in Packaging Production

Introduction: As the packaging industry evolves, the need for precise and efficient production methods becomes increasingly important. Grooving machines, essential in the manufacture of rigid boxes and other packaging types, offer a solution by providing exact grooves necessary for precise folds and clean assembly. This article explores how grooving machines enhance the production process and the overall quality of packaging.

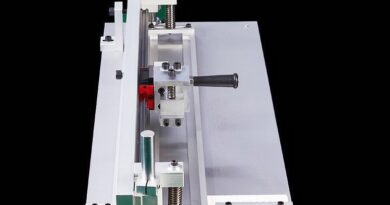

How Grooving Machines Work: Grooving machines are specialized tools designed to prepare packaging materials such as cardboard or heavy paper by creating clean, precise grooves. These grooves allow the material to be folded without bulging or breaking, which is crucial for the structural integrity of the final product.

Key Benefits:

- Enhanced Precision: Grooving machines deliver highly accurate grooves, ensuring that each fold lines up perfectly, which is essential for the final product’s appearance and durability.

- Improved Production Speed: By automating the grooving process, these machines allow for quicker production times, enabling manufacturers to increase throughput and meet larger orders more efficiently.

- Reduced Waste: Precise grooving minimizes material waste, contributing to cost savings and more sustainable production practices.

Applications in Industry: Grooving machines are versatile and find applications across various sectors, including:

- Luxury Packaging: Essential for creating the high-quality boxes used in luxury goods packaging, where presentation is as important as the product.

- Food and Beverage: Used in packaging design that requires rigid and reliable boxes to ensure product safety during transport.

- Gift Boxes: Allows for the creation of custom, aesthetically pleasing gift boxes that require precise assembly.

Conclusion: Grooving machines play a critical role in modern packaging production by ensuring precision, efficiency, and sustainability. Their ability to produce exact grooves that facilitate perfect folds makes them indispensable in the industry, particularly in sectors where box quality directly influences consumer perception.