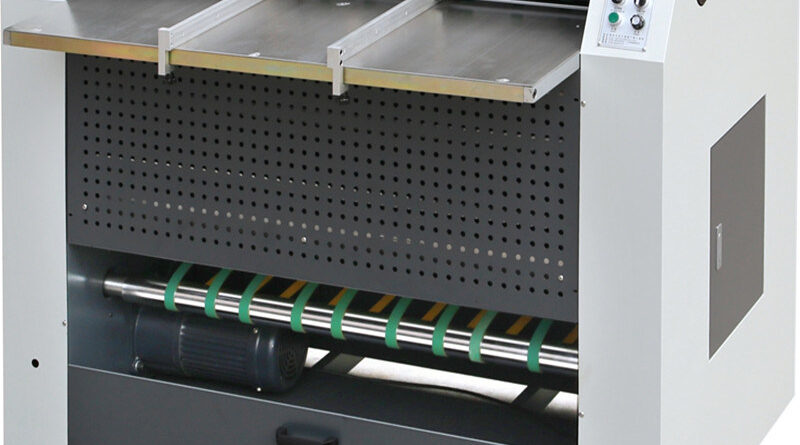

Grooving machines

The rapid advancement of technology has spurred the evolution of grooving machines. Integration with modern CNC technology has significantly enhanced their precision and user-friendliness. Advanced control systems allow for the swift production of complex patterns and special shapes, offering operators simplicity and effectiveness in use. These innovations make grooving machines indispensable, especially in the production of customized parts. Consequently, technological progress has broadened the role of grooving machines in production processes, boosting industry efficiency and product quality.

Grooving machines

Sustainable manufacturing practices are increasingly becoming a priority in today’s industrial landscape, and grooving machines are contributing significantly to this shift. By enabling precise grooving, these machines minimize material wastage, aligning with the principles of reducing resource consumption and enhancing efficiency. The precision of grooving machines ensures that materials are used optimally, reducing the amount of scrap produced and, consequently, the environmental footprint of manufacturing operations. Additionally, modern grooving machines are designed for energy efficiency, further contributing to sustainable production goals. This integration of sustainability and technology demonstrates how grooving machines not only meet the demands of modern manufacturing but also contribute to the broader goal of environmental stewardship.