Grooving Machines: A Revolutionary Force in Industrial Production

The Essential Role of Grooving Machines in Modern Industries

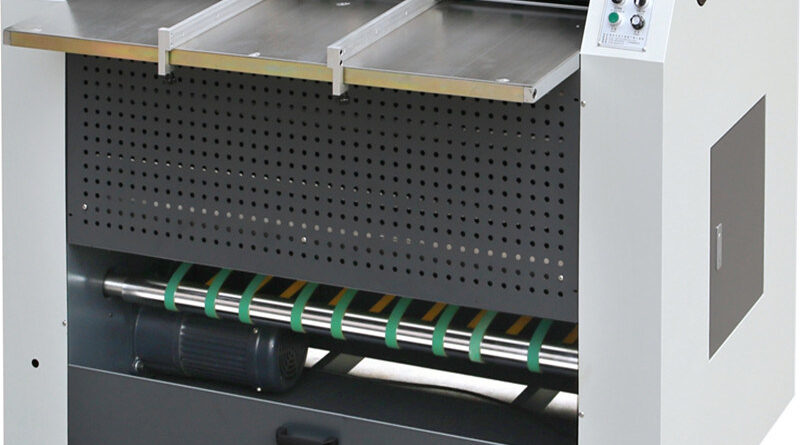

In the realm of industrial production, precision and efficiency are key determinants of success. Grooving machines have become indispensable tools by offering exceptional accuracy in cutting and shaping materials, making them fundamental in various sectors including automotive, aerospace, construction, and furniture manufacturing. These machines stand as pillars of modern production processes.

Technological Innovation and Adaptation

Equipped with advanced CNC (Computer Numerical Control) technology, grooving machines play a transformative role in manufacturing processes. This technology allows operators to achieve complex groove patterns and specialized cuts with utmost precision. The digital control mechanisms of these machines minimize operational errors while enhancing the speed and flexibility of the production process.

Boosting Production Efficiency and Sustainability

Grooving machines contribute to making production lines more efficient and cost-effective. Their ability to perform high-speed cuts increases production capacity, while precise cuts reduce material waste and elevate the quality of final products. Additionally, their energy-saving designs offer significant advantages in terms of environmental sustainability.

The Importance of Integration with Industry 4.0

Grooving machines are capable of seamless integration with smart manufacturing and Industry 4.0 concepts. By collecting and analyzing production data, these machines enable businesses to manage and optimize their processes more efficiently. This integration facilitates more responsive and flexible production processes, allowing companies to quickly adapt to changing market demands.

Material Diversity and Flexible Manufacturing

The capacity of grooving machines to work compatibly with various materials enhances flexibility in industrial production. These machines allow users to customize materials for diverse projects and applications, meeting different industry standards. This versatility makes grooving machines a valuable investment across numerous production domains.

In conclusion, grooving machines have proven themselves as a revolutionary force in industrial production. By incorporating technological innovations that significantly increase production efficiency and sustainability, these machines play a key role in meeting the manufacturing needs of the future. As industries continue to evolve, the significance of grooving machines in the production process is set to grow, highlighting their critical role in advancing manufacturing capabilities.