Grooving Machinery: Driving Precision and Efficiency in Modern Manufacturing

In the complex world of manufacturing, where precision and efficiency are paramount, grooving machinery plays an indispensable role. This specialized equipment is designed to carve grooves into various materials, facilitating essential processes in numerous industries. This article delves into the features, benefits, and impactful role of grooving machinery in enhancing production capabilities across diverse sectors.

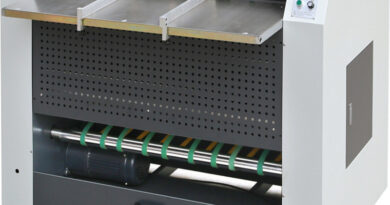

Introduction to Grooving Machinery

Grooving machinery is engineered to perform precise cutting operations that create grooves or channels in materials such as metals, wood, and polymers. These grooves are crucial for applications ranging from automotive parts assembly to intricate woodworking and piping installations. The ability to deliver precise and consistent grooves ensures that components fit perfectly, enhancing the functionality and integrity of the final product.

Key Features of Modern Grooving Machines

Modern grooving machines boast advanced features that cater to the needs of high-precision manufacturing:

- High-Precision Cutting Tools: Equipped with state-of-the-art cutting technology, these machines offer unparalleled accuracy in grooving operations.

- Versatility: Capable of handling a wide range of materials and groove dimensions, modern grooving machines can be adjusted to meet specific production requirements.

- Speed and Automation: Many grooving machines incorporate automated systems that significantly speed up production without compromising on quality.

- Digital Integration: Enhanced with digital controls, these machines allow for precise adjustments and real-time monitoring, optimizing the grooving process for various applications.

Benefits of Using Grooving Machinery

Implementing grooving machinery in manufacturing processes offers numerous advantages:

- Increased Production Efficiency: Automation and precision engineering allow for faster production times while maintaining high-quality standards.

- Enhanced Product Quality: Consistent and accurate grooving improves the overall quality of the manufacturing process, ensuring that parts fit seamlessly and function optimally.

- Cost-Effectiveness: By reducing the need for manual labor and minimizing material wastage, grooving machinery can significantly lower production costs.

- Flexibility: The ability to quickly adapt to different material types and sizes makes these machines extremely versatile and valuable in dynamic manufacturing environments.

The Impact on the Manufacturing Industry

Grooving machinery has transformed various manufacturing sectors by enabling the production of intricate and precise components at high volumes. Industries such as automotive, aerospace, plumbing, and woodworking rely heavily on the capabilities of grooving machinery to meet stringent quality and safety standards. As product designs become more complex, the demand for precision grooving continues to grow, driving innovations in machine technology.

Future Trends in Grooving Technology

The future of grooving machinery is poised for significant technological advancements. Anticipated developments include greater integration with CNC technology for even more precise control, the use of AI and machine learning for predictive maintenance and optimization, and advancements in tool materials that extend lifespan and reduce operational costs. Additionally, sustainability initiatives are expected to drive the adoption of more energy-efficient models and processes that minimize environmental impact.

Conclusion

Grooving machinery is a critical component of modern manufacturing, providing the precision and efficiency required to produce high-quality products. As industries evolve and demand more sophisticated production techniques, the role of grooving machinery becomes increasingly vital. Investing in advanced grooving technology is not just about enhancing production capabilities—it’s about securing a competitive edge in a rapidly changing industrial landscape.