Understanding Grooving Machines: Essential Tools for Refined Box Manufacturing

Introduction: In the packaging and printing industries, precision and aesthetics play pivotal roles in product presentation and functionality. Grooving machines, specialized equipment in the manufacturing of boxes, particularly rigid boxes, are crucial for ensuring high-quality outcomes. This article explores what grooving machines are, their function, and the advantages they bring to box manufacturing processes.

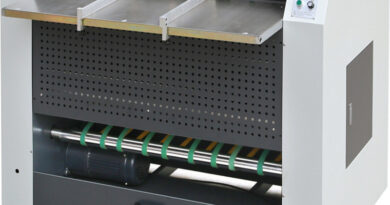

What is a Grooving Machine? A grooving machine is a device used to create precise grooves or channels in materials such as cardboard, paperboard, or MDF panels. These grooves are essential for the subsequent folding of the material into various box shapes without compromising the material’s integrity or causing unwanted creases or cracks.

Operational Features:

- Precision Grooving: Grooving machines are equipped with sharp blades or cutting wheels that accurately cut the material to a specified depth, allowing for clean and precise folds.

- Adjustable Settings: These machines typically feature adjustable settings to handle different thicknesses and types of materials, as well as to vary the depth and width of the grooves according to specific project requirements.

- High Efficiency: Designed to streamline production processes, grooving machines can rapidly prepare materials for box assembly, significantly increasing production speed compared to manual cutting methods.

Benefits of Using Grooving Machines:

- Enhanced Product Quality: Grooving machines ensure that the folds and corners of boxes are sharp and precise, which is crucial for high-end packaging that demands a premium appearance.

- Increased Productivity: Automating the grooving process minimizes the manual labor involved in preparing materials, thereby speeding up the entire production line.

- Versatility: Modern grooving machines can handle a variety of materials and custom settings, making them suitable for a wide range of packaging projects, from gift boxes to luxury packaging.

- Reduced Material Waste: Precise cutting reduces material wastage, which is not only cost-effective but also environmentally friendly.

Applications in Industry: Grooving machines are widely used across various sectors that require sturdy, aesthetically pleasing packaging solutions, including:

- Luxury Goods: For packaging premium products such as perfumes, jewelry, and high-end electronics.

- Gift Boxes: Enhancing the structural integrity and visual appeal of gift boxes.

- Marketing and Promotional Materials: Creating bespoke packaging for marketing kits and promotional items.

Conclusion: Grooving machines are indispensable in the field of box manufacturing, providing the precision and efficiency required for producing high-quality packaging. By ensuring accurate grooves for perfect folds, these machines play a crucial role in the aesthetic and functional aspects of box design. As the demand for sophisticated packaging continues to grow, the importance of grooving machines in achieving superior product presentation and structural integrity cannot be overstated. Their ability to enhance production speed, reduce costs, and improve product quality makes them a valuable asset in any packaging operation.