Technological Transformation in Grooving Machinery: Ushering in a New Era in the Packaging Industry with Google-Compatible Innovations

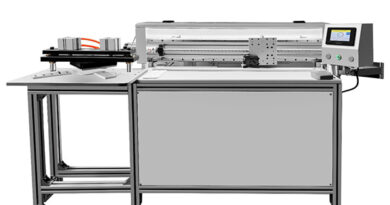

In the intricate dance of packaging and product presentation, grooving machinery plays a crucial role in creating precise folds for premium boxes and high-quality materials. The recent integration of Google-compatible technologies into grooving machinery is transforming this niche sector, introducing a new level of precision, efficiency, and smart management to the packaging industry’s backbone.

Real-time Performance Insights through IoT

At the core of this transformation is the Internet of Things (IoT), which brings real-time monitoring and analytics to the forefront of grooving operations. By embedding IoT sensors into grooving machinery, manufacturers gain immediate insights into machine performance, material usage, and operational efficiencies. This integration with Google Cloud’s IoT platform enables predictive maintenance, significantly reducing downtime and enhancing productivity by ensuring that machinery operates at peak efficiency.

Enhanced Quality Control with AI

Artificial Intelligence (AI) further elevates the capabilities of grooving machinery, making quality control more precise and automated. Utilizing Google’s advanced AI algorithms, these machines can now automatically adjust grooving depths and angles in real-time, accommodating various material types and thicknesses. This adaptability ensures that each groove is perfectly executed, maintaining consistency across batches and minimizing material waste.

Collaboration and Workflow Optimization

Beyond the machinery itself, the integration with Google Workspace revolutionizes the way teams collaborate and manage workflows. Design, production, and quality control teams can now work together seamlessly, sharing designs, production schedules, and quality reports in real-time. This enhanced collaboration leads to more efficient production cycles and allows for quick adjustments to design specifications or production processes, ensuring that the final product meets the high standards of today’s market.

Sustainability and Efficiency

The adoption of Google-compatible technologies in grooving machinery also aligns with the industry’s growing emphasis on sustainability. Through optimized machine performance and material usage, manufacturers can significantly reduce waste and energy consumption. Data analytics provide insights into how production processes can be further refined for efficiency, contributing to a smaller environmental footprint without compromising on quality or performance.

Conclusion: A Future of Enhanced Possibilities

The integration of Google-compatible technologies with grooving machinery is not just an upgrade; it’s a redefinition of what’s possible in the packaging industry. It represents a shift towards smarter, more efficient, and sustainable manufacturing practices, setting a new standard for quality and innovation. As this technology continues to evolve and integrate more deeply into the fabric of packaging production, it promises to unlock new possibilities for manufacturers and redefine the future of packaging excellence.