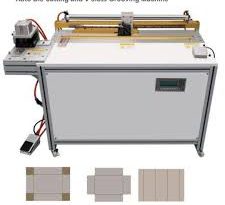

Why Choose Grooving Machinery: Enhancing Flexibility and Precision in Material Processing

In the manufacturing and packaging industries, precision in material handling can drastically improve product quality and operational efficiency. Grooving machinery is essential for businesses that require accurate grooves in materials for assembly or aesthetic purposes. This article discusses the benefits of incorporating grooving machinery into production lines and how it can transform operations by enhancing precision and flexibility.

Advantages of Grooving Machinery

- Precision Cutting: Grooving machinery offers unparalleled precision in cutting grooves into a variety of materials, including wood, metal, plastics, and composites. This precision is crucial for ensuring that components fit perfectly together, which is particularly important in industries like furniture manufacturing and automotive assembly.

- Increased Production Efficiency: By automating the grooving process, this machinery speeds up production times and reduces the workload on employees. Faster production rates enable businesses to meet larger orders more efficiently, boosting overall productivity.

- Consistent Quality: With advanced programming capabilities, grooving machines deliver consistent results, minimizing the variability that often comes with manual processing. Consistent high-quality grooves are essential for maintaining the structural integrity and aesthetic appeal of the final products.

- Versatility: Modern grooving machinery can be adjusted to handle different sizes and types of materials, making it an invaluable asset for businesses that work with a diverse range of products. This versatility allows companies to use the same machine for multiple applications, optimizing their investment.

- Reduced Waste: Precision grooving helps minimize material waste by ensuring that cuts are made exactly where needed, reducing excess scrap. This not only saves on material costs but also aligns with sustainable manufacturing practices by lessening environmental impact.

Industries That Benefit from Grooving Machinery

- Packaging: In the packaging industry, grooving machinery is used to create precise folds in cardboard and other paper materials, facilitating the assembly of intricate packaging designs that are both functional and visually appealing.

- Construction and Flooring: Grooving machines are essential for cutting slots in flooring materials, such as tiles and wood panels, ensuring they fit together seamlessly during installation.

- Automotive: The automotive industry uses grooving machinery to cut grooves in various components, where precise dimensions are crucial for assembly and performance of the vehicle.

Conclusion

Investing in grooving machinery is a strategic decision that can lead to significant improvements in product quality, production efficiency, and material cost savings. With its ability to deliver precise, consistent, and versatile cutting solutions, grooving machinery is an indispensable tool for any business looking to enhance its manufacturing or packaging capabilities. As industries continue to demand higher precision and greater efficiency, the role of grooving machinery becomes increasingly important, making it a wise choice for companies aiming to stay competitive and innovative in their markets.