The Future of Precision Manufacturing: Advancements in Grooving Machinery

In the realm of precision manufacturing, the evolution of grooving machinery stands as a testament to the industry’s relentless pursuit of innovation and efficiency. These machines, integral to creating precise grooves in a variety of materials, have undergone significant technological advancements, enabling unprecedented levels of accuracy and productivity. This article explores the cutting-edge developments in grooving machinery and its pivotal role in shaping the future of manufacturing.

Cutting-Edge Technology in Grooving Machinery

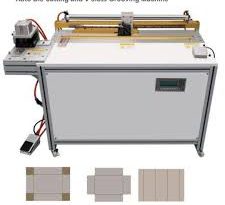

Integration with Advanced CNC Systems: The synergy between grooving machinery and Computer Numerical Control (CNC) technology has revolutionized the manufacturing process. Modern grooving machines equipped with CNC systems offer unparalleled precision, allowing for the creation of intricate grooves that meet exact specifications with minimal waste.

Smart Automation and Robotics: The incorporation of smart automation and robotics into grooving machinery has significantly enhanced its efficiency and reliability. These technologies enable autonomous operation, reducing the need for manual intervention and minimizing the potential for human error. As a result, manufacturers can achieve higher throughput rates while maintaining the quality of the finished product.

IoT Connectivity for Enhanced Performance: Internet of Things (IoT) connectivity in grooving machinery represents a major leap forward in operational efficiency. By connecting machines to a network, manufacturers can monitor performance in real time, predict maintenance needs, and optimize production schedules. This level of connectivity ensures that grooving machinery operates at peak performance, contributing to a more streamlined manufacturing process.

The Impact of Grooving Machinery on Manufacturing

Elevating Production Standards: The technological advancements in grooving machinery have set new standards for production quality and efficiency. Manufacturers can now produce components with unparalleled precision, meeting the demands of industries that require exacting standards, such as aerospace, automotive, and medical devices.

Facilitating Customization and Flexibility: The flexibility offered by modern grooving machinery enables manufacturers to quickly adapt to changing market demands and custom specifications. This adaptability is crucial for staying competitive in an industry where customization is increasingly valued by customers.

Driving Sustainable Manufacturing Practices: With an emphasis on minimizing waste and optimizing resource use, grooving machinery contributes to more sustainable manufacturing practices. The precision and efficiency of these machines reduce material waste, aligning with global efforts to promote environmental responsibility in manufacturing.