Maximizing Production with Grooving Machines

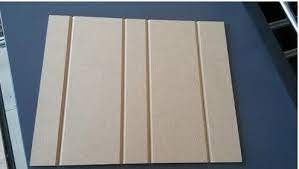

In the realm of industrial manufacturing, grooving machines have become fundamental tools for enhancing operational efficiency and product quality. These machines, renowned for their precision and versatility, are capable of producing exact grooves on a myriad of materials. The adoption of CNC technology in grooving machines has elevated their functionality, allowing for intricate designs and consistent outputs across various sectors, including automotive, aerospace, and woodworking. The ability of grooving machines to seamlessly adapt to diverse materials amplifies their indispensability in modern manufacturing setups.

The Environmental Edge of Grooving Machines

Sustainability in manufacturing is increasingly gaining momentum, and grooving machines are at the forefront of this green transition. By optimizing material usage and reducing waste, grooving machines play a crucial role in establishing eco-friendly production practices. Their operational efficiency not only accelerates the manufacturing timeline but also diminishes the energy footprint of production activities. This dual advantage of grooving machines, where they enhance both productivity and environmental sustainability, positions them as essential assets in the pursuit of eco-efficient manufacturing processes. As the industry evolves, grooving machines continue to set new standards for how manufacturing efficiency and ecological responsibility can go hand in hand.