Grooving Machines: A Revolutionary Role in Industrial Production

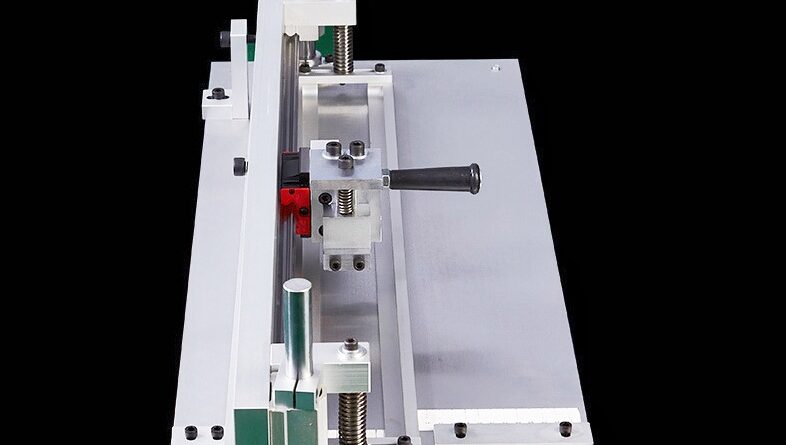

Grooving machines have transformed industries, ushering in a revolutionary change in production landscapes. With their capability to carve extremely precise grooves, these machines significantly reduce material waste while substantially enhancing product quality. Thanks to CNC technology, grooving machines can execute complex designs with perfect accuracy, thereby saving time and reducing costs in production processes.

The versatility offered by these machines, capable of working on diverse materials, extends their applicability across various sectors from automotive to aerospace, construction to furniture manufacturing. Furthermore, the integration of grooving machines with smart manufacturing technologies brought about by Industry 4.0, automates production processes, providing businesses with superior control and efficiency.

Grooving machines also contribute to sustainable production practices. They promote material savings, energy efficiency, and waste minimization, strengthening the adoption of environmentally friendly production methodologies.

In conclusion, grooving machines have become foundational to modern industrial production, creating more efficient, economical, and eco-friendly processes. The technological benefits these machines provide will continue to play a crucial role in shaping the future of production paradigms.