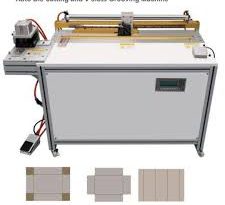

Grooving Machinery: Precision Engineering for Enhanced Packaging Design

In the competitive packaging industry, precision and efficiency are key to meeting consumer demands and enhancing product appeal. Grooving machinery plays a crucial role in this process by precisely engineering grooves into packaging materials, facilitating sophisticated designs and functional folds. This article highlights the strategic benefits of integrating grooving machinery into packaging operations, underlining its impact on production efficiency and design versatility.

Advantages of Grooving Machinery

- Enhanced Precision and Quality: Grooving machinery provides exact grooves in various materials, ensuring clean and precise folds that are essential for the structural integrity of finished packaging. This precision is crucial for complex designs and high-quality presentation, particularly in industries where packaging aesthetics are paramount.

- Increased Production Efficiency: By automating the grooving process, these machines significantly speed up production, allowing businesses to handle larger orders and reduce turnaround times. This efficiency is vital in today’s fast-paced market, where speed to market can be a significant competitive advantage.

- Material Versatility: Modern grooving machines are equipped to handle a range of materials, from corrugated cardboard to rigid papers and plastics. This versatility enables manufacturers to explore a wider array of packaging options and cater to diverse market needs.

- Reduced Waste: Precision grooving minimizes material waste by accurately sizing components according to specifications. This not only reduces costs associated with material usage but also aligns with sustainability efforts by decreasing the environmental impact of production processes.

Industries That Benefit from Grooving Machinery

- Retail Packaging: Retail products often require visually appealing and structurally sound packaging to attract consumer attention and ensure product safety. Grooving machinery aids in creating such packaging efficiently and consistently.

- E-Commerce: With the rise of online shopping, e-commerce businesses greatly benefit from durable and attractive packaging. Grooving machinery helps produce packaging that withstands shipping rigors while enhancing the unboxing experience.

- Luxury Goods: For high-end products, packaging is an integral part of the brand experience. Precisely grooved packaging exudes quality and luxury, significantly impacting consumer perception and value appreciation.

Making the Investment

When considering the integration of grooving machinery into packaging operations, businesses should evaluate:

- Operational Needs: Assess the specific grooving requirements of your product line to determine the appropriate machine specifications, ensuring the machinery can effectively meet your production demands.

- Cost Efficiency: Analyze the potential cost savings from reduced labor and material waste against the initial investment and ongoing maintenance costs of the machinery.

- Supplier Expertise: Choose equipment from suppliers with proven expertise and reliable customer support to maximize the longevity and effectiveness of your investment.

Conclusion

Investing in grooving machinery is a strategic decision that can transform packaging operations by enhancing design capabilities, operational efficiency, and product quality. As the packaging industry continues to evolve with increasing demands for innovative and sustainable solutions, grooving machinery remains a critical asset for businesses looking to stay competitive and meet the sophisticated needs of their clients.