Enhancing Efficiency with Grooving Machines

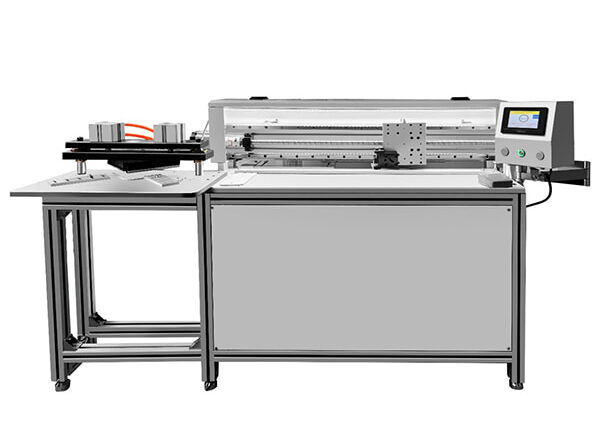

In the landscape of modern manufacturing, grooving machines stand out for their critical role in enhancing production efficiency and quality. These machines, empowered by advanced CNC technology, facilitate precise and rapid creation of grooves across a variety of materials, from metals to plastics. This capability is crucial for industries requiring high precision parts, like automotive and aerospace.

The adaptability of grooving machines to different materials and specifications makes them invaluable in achieving operational efficiency. Their integration into production lines leads to reduced waste and energy consumption, aligning with sustainable manufacturing practices. Moreover, the automation features of grooving machines minimize manual labor, streamline processes, and significantly cut down production time.

Grooving machines not only improve the speed and accuracy of manufacturing tasks but also contribute to the overall competitiveness of businesses by enabling them to meet stringent quality standards and adapt quickly to market changes. As industries continue to advance, the reliance on such efficient and versatile tools will undoubtedly increase, underscoring the indispensable nature of grooving machines in the future of manufacturing.