“Cutting-Edge Innovations in Grooving Machinery: Shaping the Future of Packaging Technology”

In the ever-evolving landscape of the packaging industry, the role of grooving machinery has become increasingly pivotal. This equipment, essential for creating precise grooves in packaging materials, has undergone significant technological advancements, leading to enhanced efficiency, accuracy, and versatility. The innovations in grooving machinery are setting new benchmarks for quality and performance in the packaging sector. Here’s an insight into the latest technological trends shaping grooving machinery:

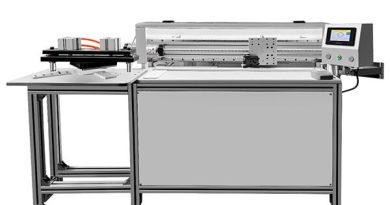

Precision Engineering: Modern grooving machines are designed with advanced engineering capabilities, ensuring ultra-precise grooves that contribute to the structural integrity and aesthetic appeal of the final product. High-precision components and control systems allow for exact grooving, essential for sophisticated packaging designs.

Automation and Integration: The integration of automation technologies has transformed grooving machinery, enabling automated adjustments and operations. This automation not only increases production speeds but also minimizes human error, ensuring consistent quality across batches. Moreover, these machines can be seamlessly integrated into existing production lines, enhancing operational efficiency.

Material Versatility: Today’s grooving machinery can accommodate a broader range of materials, from traditional cardboard and paperboard to innovative eco-friendly options. This versatility allows packaging manufacturers to experiment with different materials while maintaining high-quality grooves, meeting both creative design and sustainability requirements.

Energy Efficiency: With a growing emphasis on sustainability, the latest grooving machines are designed to be more energy-efficient. These machines consume less power, reducing the carbon footprint of packaging operations and contributing to a more sustainable production process.

Digitalization and Connectivity: Incorporating digital technologies, modern grooving machines feature connectivity options that allow for smart monitoring and control. Through IoT (Internet of Things) integration, operators can track machine performance in real-time, schedule maintenance proactively, and optimize production processes for maximum efficiency.

User-Friendly Interfaces: The adoption of touchscreen displays and intuitive software interfaces makes it easier for operators to configure and operate grooving machinery. Enhanced user interfaces reduce the learning curve and allow for quick adjustments, leading to improved productivity and flexibility in production.

Safety Enhancements: Safety in the workplace is a paramount concern, and the latest grooving machinery includes advanced safety features. These features protect operators from potential hazards, ensuring a safer working environment while maintaining high operational standards.

The technological advancements in grooving machinery are revolutionizing the packaging industry, offering manufacturers the tools to produce high-quality, innovative packaging solutions. These innovations not only enhance production capabilities but also address the growing demands for sustainability and efficiency in the global market. As technology continues to evolve, the potential of grooving machinery to impact the packaging industry positively is boundless, promising a future where packaging is not just functional but also creatively and environmentally forward-thinking.